Choosing the Right Lab Gas Regulators: Factors To Consider

When working in a professional setting that requires precise gas control, selecting the appropriate lab gas regulators is essential for maintaining safety and accuracy in your operations. In order to make sure you come to an informed decision, review this list of key factors to consider when choosing the right lab gas regulators for your needs. By carefully evaluating these factors, you can ensure that your gas regulation equipment effectively fulfills its intended purposes.

Gas Type and Required Flow Rate

Different gases require specific lab gas regulators depending on their unique properties. Before you choose a regulator, it’s important to determine the type of gas you will be working with, as well as the required flow rate.

It’s best to consult the gas cylinder’s label or the Material Safety Data Sheet (MSDS) to find this information. Once you know the gas type and flow rate, you can select a regulator designed for those specific conditions.

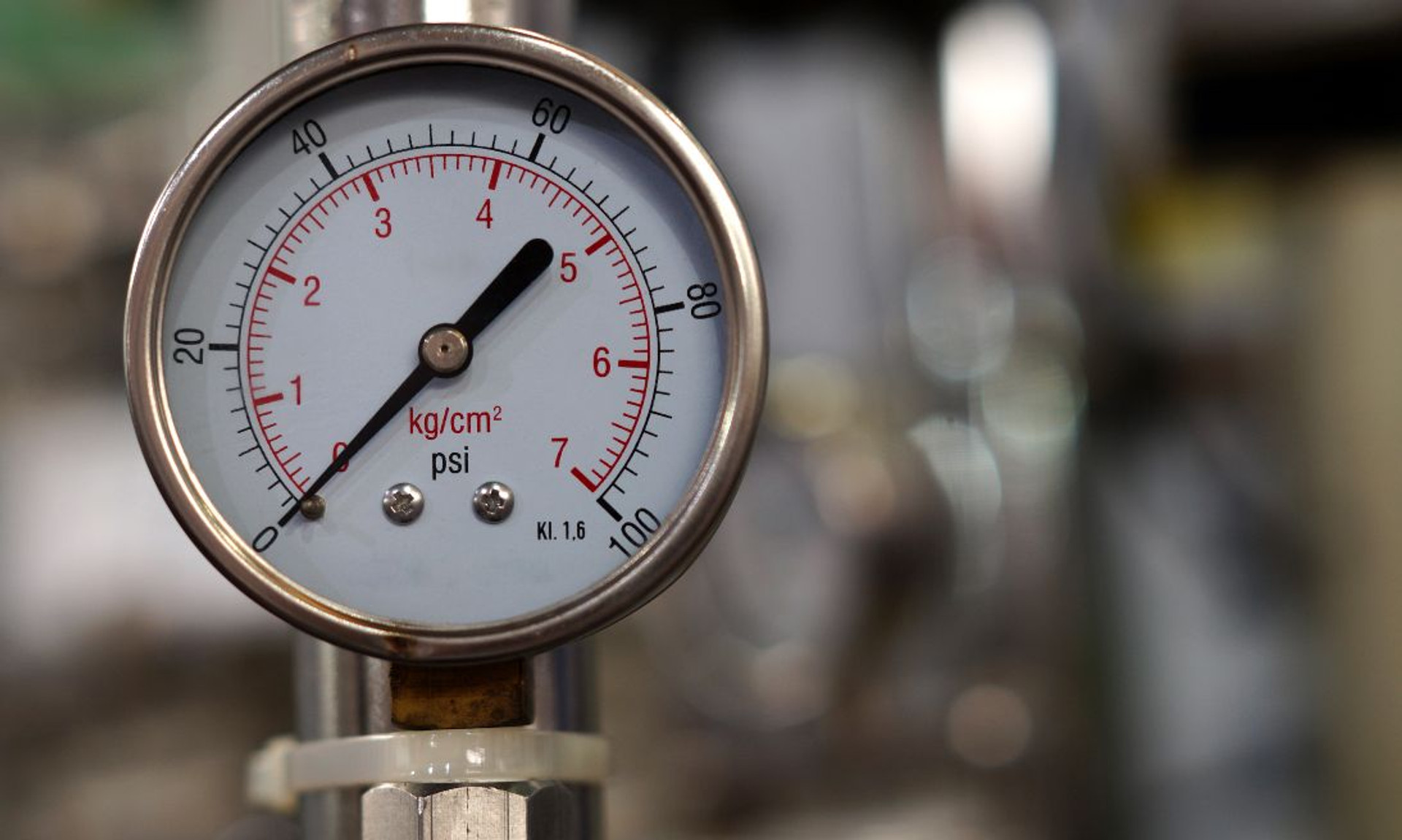

Pressure Range and Control Precision

Regulating pressure accurately is essential for a variety of applications. Make sure you select a gas regulator with the appropriate pressure range and control precision for your operations. The regulator should be able to handle both the maximum inlet pressure from the gas cylinder and the desired outlet pressure.

Additionally, the regulator should provide the level of control precision required for your specific application, such as maintaining constant pressure, allowing for gradual adjustments, or supporting rapid pressure changes.

Material Compatibility

Another crucial factor to consider when choosing a lab gas regulator is the materials used in the construction of the device. They should be compatible with the gas in use to ensure durability and prevent reactions that could compromise the safety or accuracy of the gas flow.

Common materials used in the manufacturing of lab gas regulators include brass, stainless steel, aluminum, and plastic. Be sure to select a regulator made from materials suitable for your intended gas type.

Safety Features

Of course, safety is paramount when dealing with pressurized gases, and choosing a gas regulator that incorporates appropriate safety features is crucial. Look for regulators that include pressure relief valves, gauge guards, and other mechanisms that protect the user and equipment from over-pressurization, leaks, or other potential hazards.

Ease of Use and Maintenance

The ease of use and maintenance of your gas regulator can significantly impact your workflow. Consider factors such as the regulator’s mounting options, the ease of installation, and the simplicity of the user interface when determining the regulator that will best suit your needs.

Additionally, take into account the frequency and complexity of maintenance required to keep the regulator functioning optimally. A regulator that is easy to use and maintain will ensure smooth day-to-day operations and minimize workflow disruptions.